Formex - polypropylene film

Flame retardant polypropylene insulation type FORMEX

Formex™ polypropylene film has a unique combination of electrical properties and is chemically and pyhsically robust.

Formex™ films

-

are self-extinguishing according to UL 94 V0

-

have a CTI value of 0 (>600V, insulation group I)

-

possess very good dielectric strength

-

have good HAI and HWI values

-

can be used up to 115°C (RTI)

-

are UL listed (E121855)

-

absorb almost no moisture

-

have high mechanical stability

-

can be punched and bent well

-

are used as a physical barrier (up to 2.0 mm material thickness)

-

are very resistant to chemicals

Formex™ PP films meet RoHS, REACH and WEEE requirements and can also be used as EMI/EMC shielding together with metal films.

CMC Klebetechnik offers the polypropylene film Formex™ from 0.127 mm thickness, with a self-adhesive finish if required.

The CMC 278xx product series - Flame Retardant Polypropylene Insulation Film FORMEX™ GK is particularly well suited for applications in which

-

a flame retardancy classification according to UL94-V0 is required

-

excellent voltage and tracking resistance is desired (cti > 600V)

-

a maximum temperature rating of 115°C is sufficient

-

the material is to be used as a 3D - punched part (folded, bent)

-

good dimensional stability and very low water absorption is advantageous

Formex™ GK is particularly suitable for applications in information and communication technology equipment, power supplies, medical devices, etc. The material meets the requirements of, for example, DIN EN 60950, DIN EN 62368 and UL 60950 standards regarding the minimum thickness of insulation in devices (e.g. switch-mode power supplies) at line voltage with a single-layer insulation layer (0.4 mm between active electrical parts and ground).

In addition, the polypropylene film Formex is excellently suited for the production of fire protection envelopes or fire barriers, which are otherwise usually made of e.g. sheet metal or injection molded parts (e.g. switching power supplies, frequency converters).

Formex™ is used in particular in high-voltage technology (e-mobility) because, in addition to flame retardancy, the CTI value is also very good. For insulation films of insulation material group I, the required creepage distances according to IEC 60664 insulation coordination are only half those of many high-performance materials (e.g. PEEK, PI, PPS, etc.). Formex™ is therefore the ideal material in high-voltage battery boxes, for insulating busbars (bus bars) and as housing linings for high-voltage control units with metal housings.

The products are available at UL under the number E121855 listed.

They comply with the European Directive RoHS and no banned halogen flame retardant is used.

Here you can find the data sheet in PDF format.

Nitto transfer adhesive D 9500

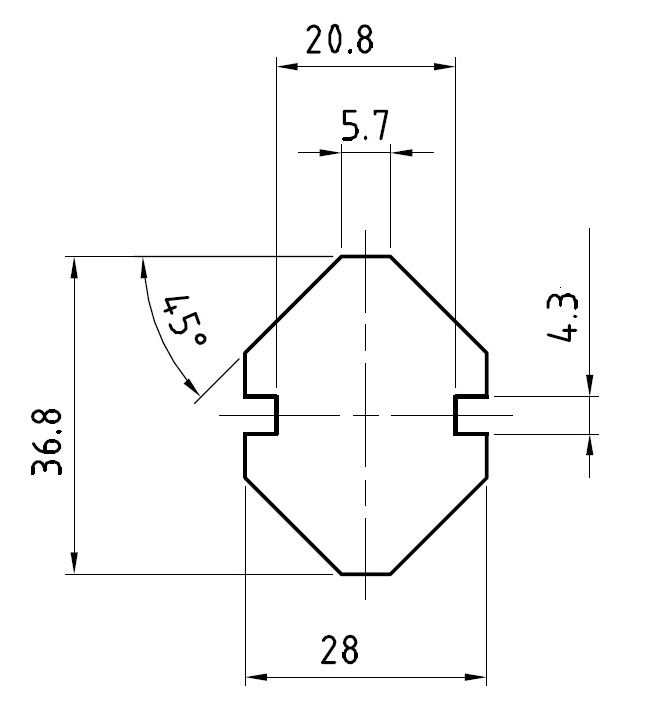

Die-cut parts for RM coilformers

RM (Rectangular Module Core) coils are characterized by very good transmission behavior with good magnetic shielding. When mounting on printed circuit boards, it may be necessary to insulate the ferrite core from the conductor tracks that run under the core. Self-adhesive die-cut parts made of CMC 27xxx Formex® are suitable for this purpose.

This product series includes material thicknesses from 0.127 mm to 1.57 mm. The polypropylene material used is UL listed, has a very good CTI value of 0 and is classified as non-flammable in V0 according to UL94. The continuous service temperature is 115°C and the material is RoHS compliant.

You will receive the Die-cut parts adapted to the design RM 12 and RM14 as well as die-cutted in other sizes or shapes if required (from 1000 pcs.).

The die-cut is self-adhesive for easy installation.