To achieve a good bond with technical adhesive tapes, the following points are crucial:

Surface preparation

Temperature

Contact pressure

Time

Surface preparation:Make sure that the surfaces to be bonded are clean, dry and free of dust, grease, oil or other contaminants. Thorough cleaning (e.g. with isopropyl alcohol) or even pre-treatment (such as sanding or priming, depending on the material) may be necessary.

Temperature: The temperature of the adhesive tape and the surfaces should be within the optimum range for the adhesive tape used (usually between 15°C and 30°C). Avoid extreme temperatures during application, as these can impair the adhesive strength.

Contact pressure: Sufficient and even contact pressure is essential to ensure that the adhesive can wet the surface well. A contact pressure of approx. 20 N/cm² is usually sufficient to achieve good wetting and thus the basis for a strong bond. Use suitable tools such as a pressure roller for this purpose.

Time: The full final adhesive strength is often only achieved after a certain time, typically within 24 to 72 hours. During this time, the adhesive flows into the microscopic unevenness of the surface and wets it completely. Avoid subjecting the bonded joint to heavy loads during this time. Low temperatures slow down the process of complete wetting of the bonded surface, while slightly higher temperatures (e.g. 50-60°C) accelerate the process.

Processing instructions for special products:

Further information on processing technical adhesive tapes

Surface finish

The surface of the parts to be bonded must be dry, grease-free and clean. A sign of surfaces that are not yet clean can be the formation of water beads when wetted with water. The substrate must also be firm for bonding. Remove loose layers of paint etc. beforehand

Mechanical cleaning

Depending on the application and base material, the effective bonding area can be increased by roughening. The roughening depth must be well below the adhesive layer thickness (good anchoring of the adhesive in the roughened surface).

Chemical cleaning

Grease, oil and other release agents as well as dirt can be removed with cleaning agents such as acetone, toluene, isopropanol and ethyl acetate. It must always be checked first whether the solvent used is suitable for the material to be cleaned. When using solvents, it is essential to observe the manufacturer's safety instructions.

Gentle cleaners for removing adhesive residue

Solvent 50 Super (Kontakt Chemie), Order No. 812031-12 at Conrad, 92530 Wernsberg-Köblitz, Tel. 09604/408988 Protect cleaned surfaces from re-soiling (lint, fingerprints, etc.). Preferably apply immediately.

Surfaces with low surface energy

With non-polar plastics such as polypropylene PP, polytetrafluoroethylene PTFE (e.g. Teflon®), polyethylene PE, rubber, silicones, there are naturally problems when bonding with standard adhesive tapes. There are special adhesives for this, which you should ask us about. The surface should also be chemically or physically roughened (e.g. corona pre-treatment).

Processing temperature, final strength

The most favorable processing temperature is approx. 20°C. Bonding below 10°C should be avoided. If the temperature differences between the parts to be bonded are too high, condensation may form, preventing proper bonding.

The adhesive tape should be applied with the highest possible pressure (depending on the material and workpiece). Adhesives are viscoelastic and flow into the unevenness of the substrate. The final adhesive strength is achieved with most adhesive tapes after a dwell time of around 72 hours. This time can be shortened by appropriate heating.

Thermosetting adhesives

Heat-curing adhesives are already largely resistant to impregnating varnishes when delivered. Subsequent heat treatment stabilizes this resistance. Recommended temperatures: 1 hour -150°C, 2 hours - 130°C, 4 hours - 100°C. In most cases, these adhesives can also be used without tempering.

PVC, plasticizer

Bonding with soft PVC is critical, as plasticizer diffusion can lead to a deterioration in the cohesion of the adhesive layer.

UV irradiation, outdoor use

Not all plastics are suitable for permanent outdoor use in sunlight. Among the technical films, polyester in particular can become brittle after a few months of intense sunlight. We offer special types of adhesive tape for outdoor use. Please contact us if you are planning to use this type of tape in such conditions.

Impregnating varnishes, impregnating resins

Due to the large variety of different impregnating agents, it is not possible to make generally valid statements. In particular, impregnating agents containing styrene can be problematic. In many cases, only tests can help here, which we are happy to carry out in-house using the samples you provide.

Backside treatment

Backside coatings or backside preparations improve the unwinding behavior of the adhesive tapes. They prevent the adhesive coating from sticking to the back of the tape after storage. Almost every self-wound adhesive tape on the market has such a release coating.

Download

You will find these instructions for printing here.

Information on the shelf life and storage life of our adhesive tape products before and after use

Due to their nature and chemical composition, our products generally have a limited shelf life or storage life in their unprocessed state. Our warranty period is generally 12 months, but may be shorter in individual cases. However, most adhesive tapes can be stored for three to five years without any significant loss of quality if stored correctly. Exceptions are, for example, fabric adhesive tapes, which build up greater adhesion to the reverse side.

For optimum workability, the storage conditions should be strictly adhered to. This means that the adhesive tapes should be stored in their original packaging in a dry place at temperatures between 15-20 °C without direct sunlight.

Always store the adhesive tapes upright, as otherwise pressure marks can restrict their workability.

Adhesive tapes that are removable (short-term applications) are subject to shorter periods of use, as the adhesive strength to the substrate increases with the period of use. The customer's own tests are usually required to be able to make a final statement. A few specific adhesive tapes or functional coatings are subject to shorter periods of use. We will be happy to send you the relevant technical data sheets on request.

Removing the cover (liner)

Double-sided adhesive tapes or so-called transfer adhesives are usually provided with only one protective cover (siliconized paper, siliconized films).

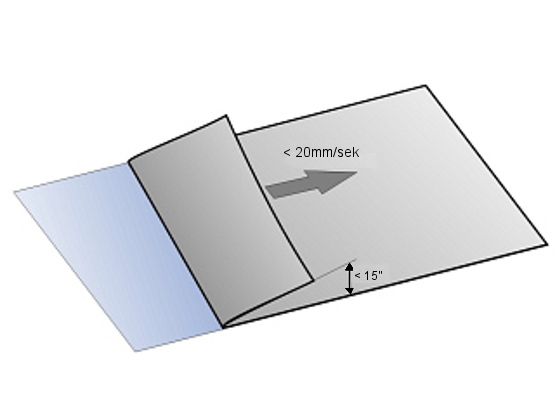

After applying the adhesive tape (the transfer adhesive film), you should wait at least 10 minutes to achieve good results before slowly peeling off the cover at a shallow angle. This prevents the adhesive surface from lifting off the substrate and creating air bubbles, for example.

With double-sided adhesive tapes that are covered on both sides (twice with siliconized paper or alternating sides of paper and transparent PET film or transparent PE film), the transfer adhesive film adheres differently to the two cover materials. In this case too, it is important to peel off the first, less adherent cover material at an acute angle so that the adhesive film does not unintentionally detach from the other cover.