Adhesive tapes for battery production

Products for a safe EV battery

The lithium-ion batteries in modern electric vehicles are constantly being developed further. Not only the power density and charging time are being optimized, but also the safety of the battery. Sophisticated manufacturing processes, sophisticated battery management systems (BMS) and battery chemistry designed for safety (e.g. LFP; lithium iron phosphate batteries, NMC) help to make the battery a fail-safe component of a vehicle.

In order for battery packs in electric vehicles, e-bikes or energy storage solutions (e.g. UPS/UPS) to function safely, numerous boundary conditions must be observed. These relate to temperature, but also to vibration-resistant fastening, the consideration of size changes (swelling) during charging and the tightness of the encapsulation.

Functions of CMC adhesive tapes:

-

Polyester film adhesive tapes for mechanical fastening and bundling

-

Flame-retardant polypropylene films as a fire barrier (propagation protection)

-

Thermally conductive electrical insulation made of Kapton® MT films (TIM) for optimum thermal coupling of battery cells with high electrical insulation. Also available with thermally conductive acrylate adhesive

-

Nomex® aramid paper as non-combustible thermal insulation and fire barrier in the event of thermal runaway of individual cells

-

Double-sided adhesive tapes For fastening and fixing printed circuit boards, cables and for cell-to-cell assembly

-

Thermally conductive silicone foils and Gap filler for thermal management (TIM) for optimum thermal connection of the cells to the housing

-

Flame-retardant polycarbonate films as barrier material and electrical insulation

-

Kapton® films and adhesive tapes as a high-performance insulation and flame-retardant barrier with a very high reserve (polyimide can be exposed to temperatures of up to 450°C for short periods) and, like Nomex®, is used to protect against the propagation of a cell fire

-

Acrylic foam adhesive tapes with thicknesses from 0.2 mm to 3 mm for sealing and mechanical damping of vibrations

-

Laminates made of different products (e.g. foam and foil) for sealing, damping and compression are possible

-

Flexible insulation foils and die-cut parts for busbars and flexible printed circuits (FPC).

In use with lithium-ion batteries:

Cell-to-cell bonding

Electrical insulation

Fastening thermal runaway protection products

Protection against corrosion

Adhesive tapes with Easy Release liners

Wrap-around adhesive tape for lithium-ion batteries

All CMC Klebetechnik products meet the highest industrial standards and are based exclusively on suitable, industrially used products. All films and adhesive tapes are also available in the form of die-cut parts (molded parts). CMC has extensive machinery for the production of die-cut films and adhesive tapes. Cutting plotters are used for initial samples and small series. For large series production, stroke die-cutters or highly efficient rotary die-cutting machines are used to keep unit costs low.

CMC adhesive tape solutions are characterized by

-

Excellent dielectric strength with low material thickness

-

Good adhesion to polar surfaces (e.g. steel, aluminum, polyamides, polyimides and polyester resins) and in many cases also to non-polar surfaces (PA, PP, PE)

-

For processors: good punchability and advantages during application (Easy Release Liner)

-

Customization possible as CMC is the manufacturer

-

Numerous films with flammability classification according to UL 94 / FMVSS302

-

Tight tolerances of +- 0.2 mm cutting width and +- 0.3 mm for punched parts (more precise tolerances available on request)

-

Adhesive tape solutions often replace more complex assembly and offer quick and durable solutions for functional tasks

-

Weight advantages compared to other fastening and securing methods

-

Process advantages during processing (simplified assembly, no curing times, accurate shape, low thickness tolerances)

Adhesive tapes and stamped parts from CMC Klebetechnik fulfill numerous functions in battery storage systems (solar storage, EV storage, e-bicycle, rechargeable tools) and can contribute significantly to the safety of lithium-ion battery packs, to a reduction in assembly time and a reduction in size.

Adhesive tapes and stamped parts used for lithium-ion batteries

Cell-to-cell bonding

Double-sided adhesive tapes with a polyester or Kapton® carrier from CMC Klebetechnik combine excellent electrical insulation with the advantage of a shear-resistant mechanical connection. Thermally conductive variants can be offered where required.

Unlike liquid (2K) adhesives, these tapes do not require time to cure and offer instant adhesion. Adhesive tapes are therefore an excellent assembly aid for bonding between individual cells and do not require mixing and dispensing equipment.

Electrical insulation

Electrical insulating tapes from CMC Klebetechnik are suitable for test voltages of up to approx. 4,000 V from a thickness of 25 µm. Thicker insulating tapes are available for higher test voltages. Insulating tapes made of Kapton®, Nomex® or Formex® also form a good flame barrier. These tapes are listed in accordance with UL94 V-0 (FMVSS302). The electrical insulation tapes can also be used to insulate rigid or flexible busbars and FPCs (flexible printed circuits).

Fastening thermal runaway protection products

In unfavorable cases, lithium-ion batteries can self-ignite. To prevent such a fire from spreading too quickly (GTR 20, 5 minutes), protective products (thermal runaway barrier material) are inserted between the individual cells or modules. These can be mica-, aerogel-, aramid- or ceramic fiber-based products, for example. Double-sided adhesive tapes from CMC Klebetechnik can be used for easier handling during assembly and to attach these sensitive products. These adhesive tapes have a dimensionally stable film core and offer mechanical stabilization of these sensitive products in addition to electrical insulation. If required, Thermal Shield products can also be completely wrapped with adhesive tapes from CMC Klebetechnik.

Protection against corrosion

Numerous different metals are used in battery modules and entire battery packs (copper, aluminum, steel, etc.). In the presence of an electrolyte (moisture), oxidation (rust) and electrochemical corrosion occur. To prevent galvanic corrosion of different metals, the ingress of moisture must be prevented. Acrylic foam adhesive tapes, for example, can make a significant contribution here. As a seal, they combine very good bonding with elastic compensation of dimensional tolerances.

Adhesive tapes with Easy Release liners

CMC adhesive tapes can be used to produce functional laminates. Double-sided adhesive tapes are used, for example, for the self-adhesive finishing of compression foam (compensation of cell swelling during the charging process) or for laminates of metal foils and insulation foils. Self-adhesive die-cut parts made from insulation foils or thermally conductive TIM products also offer assembly advantages. CMC Klebetechnik uses siliconized films and silicone papers with easy release as a protective cover (liner) for the adhesive side. This facilitates further processing, e.g. in automated process steps.

Wrap-around adhesive tape for lithium-ion batteries

For manufacturers of lithium-ion batteries, CMC Klebetechnik offers wrap-around adhesive tapes. These adhesive tapes are more resistant to hydrolysis than conventional polyester adhesive tapes and cheaper than polyimide adhesive tapes, for example.

The CMC 61100 adhesive tape is based on a class F (155°C) film for electrical engineering, which is characterized by its high ageing stability. It absorbs significantly less moisture than polyester films and is much more resistant to hydrolysis (see box for explanation). The high-performance acrylate adhesive also adheres well to LSE surfaces and is chemically very resistant. Its shear strength is excellent even at elevated temperatures and reliably seals e.g. battery wraps (jelly rolls).

The mechanical and electrical properties of the film are comparable to those of polyester films, so that a 1:1 replacement is easily possible. As a coater, CMC Klebetechnik can adjust the layer thickness of the adhesive between 10µm and 60µm if required. Other films and film thicknesses are also possible.

The CMC 61100 special adhesive tape for the production of lithium-ion batteries is available in widths from 3.6 mm to 400 mm or as finished die-cut parts on a roll.

Adhesive tapes and die-cut parts from CMC Klebetechnik

-

improve electrical safety

-

offer excellent mechanical protection

-

help to reduce the risk of fire

-

protect against critical environmental influences

Write to us or contact your personalContact person directly.

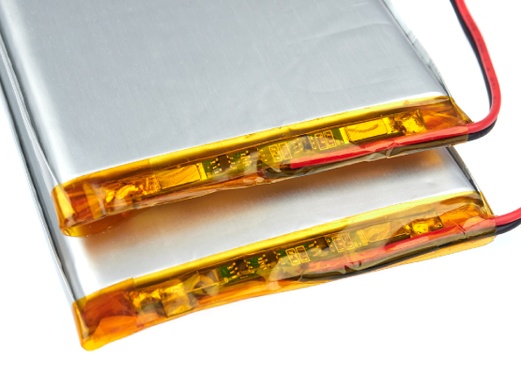

Photo: Lithium-ion polymer rechargeable batteries (abbreviated as LiPo, LIP, Li-poly). isolated on white. iStock. Teodor Costachioiu