Hydrogen technology

Adhesive film for PEM fuel cells and PEM electrolysis cells

CMC Klebetechnik supplies the bonding solution to ensure maximum operational reliability with minimum height in fuel cells. In addition to the CCM (Catalyst Coated Membrane), the gas diffusion layers (GDL) and the sub-gasket film are the components of the membrane electrode assembly (MEA) - the central element of a PEM fuel cell and a PEM electrolysis cell.

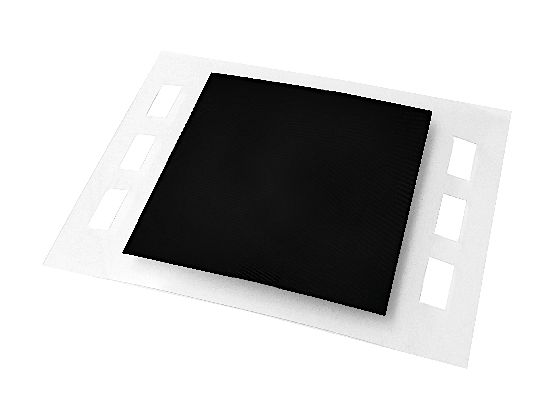

CMC Klebetechnik's subgasket films made from PEN films (also PEEK or PPS if required) are designed for durability, good processability on automated production systems and neutrality in the CCM environment.

Tasks of the sub-gasket film:

- the support film keeps the MEA taut

- it reliably separates the media (H2, O2) from each other

- it seals the system against leaks

- the frame film facilitates automated assembly (Picture-Frame Catalyst Coated Membrane; Membrane Electrode Assembly).

- Maximum packing densities (reduced device size) are possible when using thin film

- The adhesion to the edge of the CCM is almost non-existent and can be very small (smallest possible overlap) No "poisoning" of the MEA by adhesive or film

- Electrical insulation of the bipolar plates (high dielectric strength)

- Deformation-resistant films for low settlement behavior

-

The frame film relieves the CCM of mechanical stress in the edge area (the thin ion exchange membrane tends to perforate in the edge area)

CMC Klebetechnik offers as standard for EME/MEA assembly in PEM cells a PEN -film with a heat-activated adhesive (CMC 61325). The film and adhesive are hydrolytically stable and can therefore be used permanently in fuel cells. The adhesive used allows a very narrow lamination surface of the retaining film on the actual functional membrane.

The adhesive is non-sticky at room temperature. This makes it easier to apply during subsequent processing steps (e.g. pick-and-place). Even subsequent position correction is possible.

For manufacturers who want to dispense with the heating process in the automation process, there is also a adhesive version (CMC 61145). In this product, the subgasket film and the CCM are simply bonded together by lamination under pressure.

As CMC Klebetechnik coats the products itself, modifications such as different film materials, other adhesives or thickness changes are possible at any time. Please get in touch with us.

Adhesive tapes for MEA production

Production aid for MEA designs in fuel cells

Hydrogen technology for a decarbonized future

High-temperature PEM cells

Thermal management on fuel cell stacks

Fuel cells for hybrid drives

Sealing films for subgasket assembly in FC and RFB stacks

Further information on PEN films / PEN adhesive tape

Further information on Kapton films/ Kapton adhesive tape

Alternative "self-adhesive coating" for short cycle times

However, in order to achieve particularly high cycle rates, the heating step for melting the adhesive can be disruptive. CMC Klebetechnik therefore also offers a at room temperature (CMC 61145). In this case, the film coated with the catalyst layer can be bonded to the subgasket film by simple "placement". No heating is necessary, especially none that could reach the load limits of the CCM.

Tests have shown that the acrylate adhesive used by CMC Klebetechnik even increases its adhesive strength slightly under the typical cellular stresses (temperature and hydrolysis).

Due to the considerable pressure load within fuel cell stacks, mechanical deformation of the subgasket film can occur, depending on the geometries of the seals and bipolar plates used. It is therefore always possible to use thicker films (50µm, 75µm - depending on availability). Kapton® films are a possible alternative, particularly due to their high rigidity, even at elevated temperatures.

Customer-specific changes - in the simplest case, modifications to the material thicknesses - are just as possible in a joint development as adhesive systems adapted to special requirements (e.g. adhesion to repellent surfaces, SPEEK, Nafion® from Qnity (formerly DuPont), Celtec® from Advent Technologies, fumapem® from Fumatech) for alkaline fuel cells (AFC) or phosphoric acid fuel cells (PAFC) and other special shapes).

In addition to adhesive films for the production of the frame film (sub-gasket), there is also the option of sealingly bonding moistening nonwovens. These fleeces improve the service life and efficiency of larger fuel cells by actively influencing the moisture content of the PEM membrane. Air humidification is an important component of many PEM fuel cells for optimum membrane humidification. Durable and reliable sealing and bonding are typical tasks for acrylate adhesive tapes.

Products for use in fuel cells

| CMC type | Properties |

|

| CMC 61325 Laminate: PEN film with heat seal adhesive Adhesive: Polyester resin based heat seal adhesive Film thickness: 0.025 mm Total thickness: 0.040 mm |

CMC 61325 is a laminating film based on a 25 μm PEN carrier film with a polyester resin-based heat-sealing adhesive on one side. The product is supplied with a PE protective cover |

|

| CMC 61145 PEN adhesive tape Adhesive: acrylate Film thickness: 0.025 mm Total thickness: 0.040 mm |

CMC 61145 is a laminating film based on a hydrolysis-resistant PEN carrier film. The room temperature acrylic adhesive is high molecular weight, temperature and hydrolysis resistant. CMC 61145 is supplied with a protective cover. |

|

|

Kapton® FN |

Kapton® FN is ideal for direct methanol fuel cells (DMFC, HT-PEM) with operating temperatures well above 100°C, for example. |

|

CMC 15141 / CMC 15142 Film thickness: 0.025 mm / 0.050 mm | Pressure-resistant PPSU (polyphenylene sulfone) film. The almost unlimited hydrolytic stability of the PPSU film also contributes to the durability and reliability of the components manufactured with it - preferably for electrolysers. The acrylate adhesive used is high-molecular, temperature and hydrolysis resistant. |

High-temperature PEM cells

For direct methanol fuel cells (DMFC, HT-PEM) with operating temperatures well above 100°C, for example, Kapton® FN is the ideal choice. This special variant of Kapton® has very good hydrolytic stability and exhibits virtually no shrinkage. Frame films made of Kapton® FN are therefore stress-free even at temperatures at which PEN films usually show approx. 0.2-0.8% shrinkage. Special, permanently elastic adhesive coatings (PSA) act as an assembly aid and above all as a sealing element (e.g. methanol reformer).

Kapton® FN also has a lower coefficient of thermal expansion of just 20 ppm/K compared to polymer films made from PEEK (45 ppm/K) and PPS (51 ppm/K). This means that Kapton® FN is significantly closer to that of steel (11.7 ppm/K) and thus avoids stresses within the stack.

An even further improved version of the Kapton® film is Kapton® 200FWR919. This hydrolysis-resistant Kapton film is also coated on both sides with a fluoropolymer layer, so that very good chemical, thermal and electrical resistance is achieved. Kapton® FWR has even better hydrolysis stability and is more resistant to pressure.

Oasis® 200TRT515, a further development for the aircraft industry, among others, with excellent hydrolytic stability and chemical resistance and neutrality, is also very suitable for use.

In addition, PVF, PVDF and PPS films can also be used, each of which has specific advantages (low water absorption, low permeation rates for hydrogen, high hydrolysis resistance).

Fuel cells for intermittent operation such as emergency power generators for measuring stations, radio systems, IT equipment, decentralized power supply for electrical consumers or charging operation for electric batteries benefit from the much simpler handling of the "fuels" for "methanol" high-temperature fuel cells (keyword CO and sulphur poisoning).

PEM electrolyzers (electolyzers) for power-to-liquid (P2L) and power-to-chemicals (P2C) or power-to-gas (P2G) can also be equipped with these films. The fuel cell process, which in principle is the reverse of the fuel cell process, means that considerable CO2 emissions can be avoided when using renewable energy.

The chemistry and mechanical structure of the adhesive film for the functional membrane can also be adapted to the customer's requirements for applications as MEAs for electrolysers.

Thermal management on fuel cell stacks

As with any conversion process, waste heat is also generated during "cold combustion" in the fuel cell. This must be dissipated in order to avoid overheating. One of the heat management techniques is to connect the fuel cell to the coolant circuit of a hybrid vehicle. Alternatively, a separate coolant circuit with heat exchanger and fan can also be used.

In many cases, the thermal connection of elements in the heat path requires a mediating layer. Dimensional tolerances, warping and differences in thermal expansion can lead to air gaps that significantly hinder heat transfer.

Heat exchangers, air coolers, condensers, cooling plates or heating elements for preheating cryogenic NT-PEM stacks can be thermally connected using thermally conductive silicone films from CMC Klebetechnik. The flexible, elastic films are highly thermally conductive and compensate for manufacturing tolerances and other unevenness. Due to the 100% wetting of the surfaces, the maximum possible cross-sectional area is available for the heat flow. The products can be used at continuous temperatures of up to 200°C.

Sealing films for subgasket assembly in fuel cells, electrolyzers and RFB stacks

Fuel cells, electrolysis, redox flow batteries and also lithium-ion batteries, for example, have one thing in common: they use an inner separating layer as an ion exchanger. This separating layer is also known as a separator or membrane.

Adapted to the respective technology, manufacturers use very different materials for this separating layer, whose main task is to separate the two electrolytes that release or absorb electrons. In addition to chemical resistance, ionic conductivity is therefore an important criterion. In addition, there are tasks that serve safety purposes, for example: Highly temperature-resistant separators in lithium-ion batteries prevent a metal fire even in the event of faulty operation. In the stacks of fuel cells and electrolysers, the PEN adhesive film in the form of the subgasket frame not only serves as an assembly aid, but also enables cost-effective production using the roll-to-roll process (or immediately roll-to-punched part). In the stack of the redox flow battery, it plays a key role in ensuring that the two electrolytes remain safely separated. It chemically seals the two half-cells and thus prevents cross-over of the media. Where technically necessary, films made of PPS, PEEK or other high-performance films can also be used. There are only a few limits to the coating technology of CMC Klebetechnik in this respect.

For fuel cells and redox flow batteries, CMC offers products that can be combined with the actual ion exchange membrane. Depending on the operating temperature (NT-PEMFC, HT-FC), process-typical media (e.g. vanadium-based, methanol, water) or installation method (bonding, heat-sealing), different films can be offered. Even membrane films that are difficult to bond, such as Nafion® from Qnity (formerly DuPont), can be stretched into a frame that acts as a seal, provides electrical separation and also allows the active area to be mechanically fixed (subgasket frame).

Sealing the MEA by means of bonding

The subframe around the actual functional membrane (CCM) fulfills several functions. One of the most important is to prevent media transfer between the oxygen and hydrogen sides. The subframe therefore also functions as a seal.

As a "breathing" system, a fuel cell or electrolysis stack is subject to constant expansion and contraction. This "breathing" is countered by a considerable spring force. In addition to ensuring good electrical contact, this pressure has one main aim: to ensure the system is leak-proof.

CMC Klebetechnik adhesives are physically adhesive systems which, unlike thermosetting adhesive systems, remain permanently elastic. The long-term adaptation to e.g. thermally induced micro-movements has the disadvantage that the adhesive remains mobile under pressure. In this respect, adhesives from CMC bonding technology are similar to the behavior of PTFE, which flows to the side under pressure (cold flow).

This may sound like a disadvantage, but it is not. The low adhesive thickness promotes a very fast "settling" of the stack after assembly. The change in length due to the displacement of the adhesive is minimal.

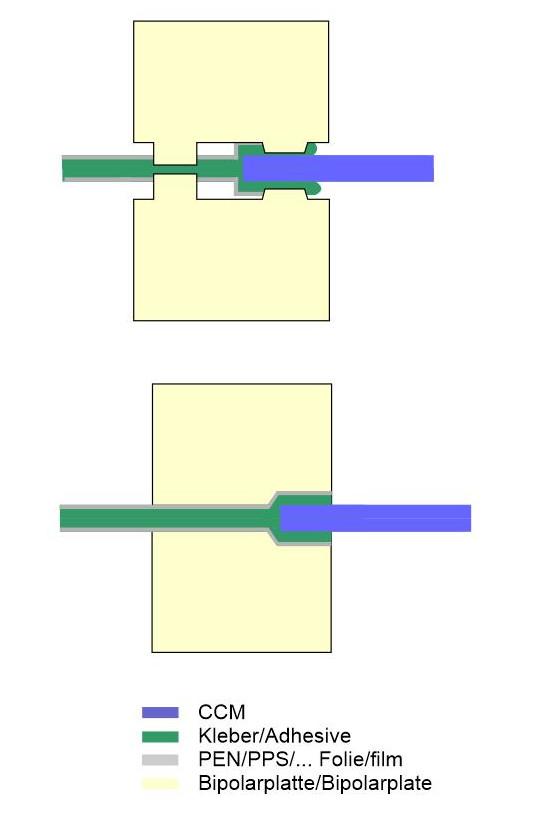

The behavior of the adhesive can even be used constructively for sealing purposes. The adhesive is deliberately displaced by an elevation incorporated in the pressing area. The pressure-resistant carrier film (PPS, PEN, PET, ....) then forms the stop for the seal.

As CMC adhesive coatings behave like viscous liquids, a particularly "large" contact surface can also prevent the stack from settling. Liquids cannot be compressed and adhesives that cannot move to the side cannot be compressed either.

Beide Dichtungsprinzipien sind in der folgenden Skizze dargestellt: