When we open a bottle of beer, we not only lift the crown cap, but also open the seal between the metal and the neck of the bottle.

This example alone shows that seals must be able to do more than "just" seal. They should remain in the installed location (the crown cap) before use and must not change the contents in an unacceptable way later on.

Aggressive chemicals in particular require highly resistant materials such as CMC 75100 from PTFE (e.g. Teflon®) or CMC 77701 from ETFE, to seal containers accordingly. Resistance lists of the individual materials help to find the most suitable one. In electroplating and etching technology in particular, chemicals are used that usually require fluorinated materials such as PTFE or ETFE. As entire containers made of these materials are expensive, only the inside is usually lined. A die-cutted sealing part is inserted into the lid, which is pre-assembled using high-quality adhesives that are often highly resistant to chemicals.

An example from CMC Klebetechnik of such a sealing part is the diaphragm of a diaphragm pump. With the help of a drive, the diaphragm is repeatedly deflected from its rest position, generating pressure and vacuum. When used appropriately, media can be transported in this way.

In this specific case, hydrocarbon-based solvents are pumped through analysis devices. Only a combination of high-quality rubber and PTFE laminated with adhesive was able to guarantee a permanent seal for the pump. The rubber takes over the elastic work and prevents the PTFE from breaking under permanent bending stress. The PTFE, on the other hand, is a virtually inert material that prevents the diaphragm seal from disintegrating.

In addition, it does not alter the sample liquid in any way by releasing substances. Just as you would expect from the seals on a beer bottle.

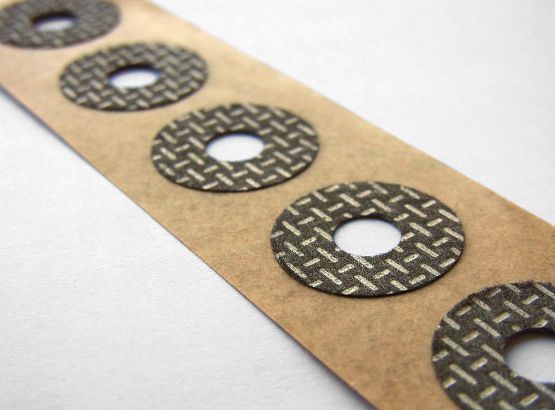

A completely different example is a die-cutted part made from a metallized nonwoven. It is equipped with an electrically conductive adhesive and "seals" the housings of industrial computers as an electrically conductive washer. The die-cutted parts prevent the immediate area of the housing screw holes from being insulated by the paint. This creates a Faraday cage after assembly, which is EMC-tight.

However, seals made of silicone or chloroprene rubber can also be fitted with self-adhesive tapes from CMC Klebetechnik. Easier pre-assembly and a reliable hold, even if the seal is opened and closed several times, are advantages that speak in favor of this technology.

Adhesive tapes for sealing applications