In various product standards of electrical equipment (e.g. UL 1012), specific insulation materials are described for insulation. These are, for example, insulations between live parts and grounded enclosures. Many standards are already several dozen years old. Despite regular revision, insulation products originating from the early days of the standard in particular persist because of long-term experience in field use. However, they are no longer used today, or only to a limited extent.

So that modern insulation products can also be added when the standards are revised, so-called equivalence factors are used more frequently. These supplement the standard texts with more modern products such as polyester films, PTFE or aramid paper. In doing so, they are placed in a specific relationship to the old insulating materials.

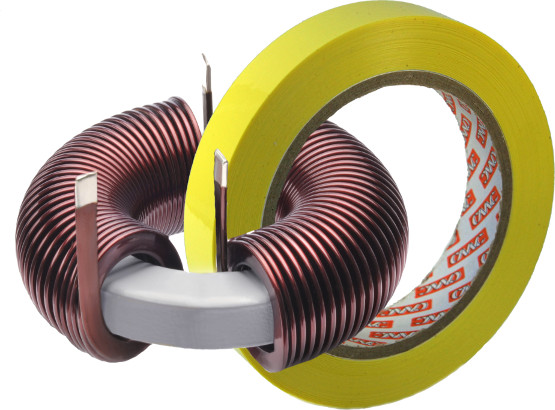

For example, UL 1012 (power supplies) describes either waxed paper or vulcanized fiber with a thickness of 0.8 mm as the material to be used for insulation in transformers between live parts. Two products that are very uncommon today.

In order to be able to use more modern insulation materials, an additional table was added to the standard. It contains a list of factors indicating how much better these materials are compared to wax paper or vulcanized fiber.

Example from Table 28A.3 of UL 1012:

The equivalent thickness of polyester films compared to the vulcanized fiber material is 1/4. Or in other words, instead of the prescribed 0.028 inch (0.71 mm), you can use a 0.19 mm PET film.

Unfortunately, such "correction factors" are sometimes not easy to find in standards. However, until the general revision of a standard to the latest status, they represent a possibility to include additional insulation materials relatively easily.

Equivalence factors for insulation materials