Simple LED luminaires, which often only use an extruded aluminum profile without good coupling of the LEDs to cooling surfaces, often have a service life of less than 25,000 hours.

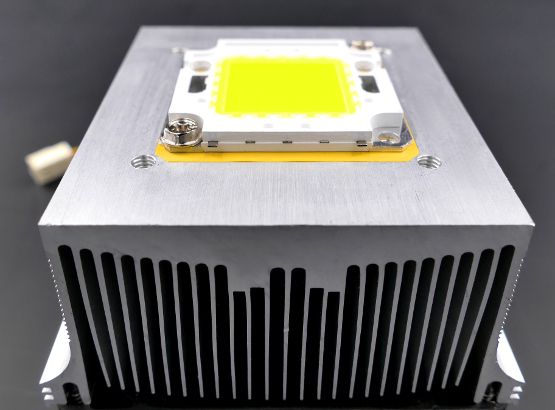

If longer power-on times are planned or trouble-free operation over many years is desired, there is no getting around thermal management. Well-known systems such as heat sinks, heat pipes, heat conducting pastes and heat conducting films have been used successfully for many years in electronic devices such as laptops or tablet PCs. These technologies are also ideally suited to making high-quality LED lighting durable. Operating times of up to 75,000 hours can realistically be achieved in this way.

With a burning time of 10 hours per day, this corresponds to a service life of around 20 years.

Compared to other types of lighting, LEDs also produce significantly less infrared radiation. In greenhouse construction, this means that the lamps can be installed significantly closer to the plants than high-pressure sodium vapor lamps or halogen lamps. As the light intensity decreases with the square of the distance, more plant-effective light can be introduced into crops in this way. In addition to improved plant growth rates, this significantly reduces energy consumption compared to traditional lighting methods.

However, heat management is also necessary in the constant current sources (ballasts for LEDs, also known as LED drivers). The transformation of the available voltage (120-400 VAC) also generates power loss at LED outputs of 100-1000 W, which must be reliably dissipated by the electronic power components. Due to the high voltage, galvanic isolation (electrical insulation) is often an important part of the thermal path.

Advantages of thermal management for LEDs

Longer switch-on times

Trouble-free operation

Operating times of up to 75,000 hours

Would you like to find out more about our thermal management products for LEDs? Visit us at the Light + Building trade fair 2020 in Frankfurt.

08.03. - 13.03.2020 - Stand: 8.0 K41

Thermal management for high-performance LED lamps in greenhouse lighting systems