A CMC adhesive tape is made up of several components that together give the desired, specific properties. For most applications, it is important to find the right combination of materials so that the adhesive tape can be used successfully.

In general, a tape consists of:

Carrier material

Adhesive type

Surface to be glued, texture

Technical requirements such as UV resistance, weathering, temperatures, abrasion, etc.

Carrier material

The backing material is the actual functional layer in most single- and double-sided adhesive tapes. The material used brings mechanical stability (e.g. glass fabric), electrical insulation (e.g. Kapton® film), sliding properties (e.g. PTFE or UHMW-PE) or chemical resistance (e.g. ETFE) to the adhesive tape "system". To the products.

The following table lists some carrier materials as examples:

Fabrics: acetate silk fabrics, glass fabrics, metallized PA fabrics

Paper: Electro crepe paper

Films: Mylar® and Hostaphan® (PET), Teonex® (PEN), Nomex® (meta-aramid paper), Kapton® (PI), PTFE, Makrofol® (PC), Aptiv™ (PEEK), Formex® (PP), etc.

Metals: copper, tinned copper, aluminum (on request also steel, zinc, tin)

Transfer adhesives: acrylate adhesive films and silicone adhesive films

Foam and nonwovens: PE foam, PA nonwovens

Adhesive types

Another important detail of an adhesive tape is, of course, the adhesive used and its task. In addition to its function as an assembly aid, the adhesive can also have a sealing effect, protect against corrosion, compensate for differences in thickness, and generally bond very different materials together elastically. Adhesive types are available for a very wide range of applications: from very cold to very hot, from weakly adhesive to very aging-resistant, from highly transparent to opaque black.

For detailed information on the different types of adhesives and further information on bonding, see here.

Acrylic adhesive: (ageing-resistant, very good adhesion, partly also on low-energy surfaces, high temperature resistance)

Rubber - adhesives: (often very good initial adhesion and good bonding forces, partly removable, limited aging resistance, especially with UV)

Polysiloxane adhesives: (Extremely high-strength adhesives, very temperature-, weather- and chemical-resistant adhesive bonds possible, adhesion even on repellent surfaces)

Heat seal adhesives: (Heat seal adhesives soften when heated and then bond. Non-adhesive at room temperature)

To achieve optimum results with technical adhesive tapes, certain processing specifications must be observed. You can obtain further information here.

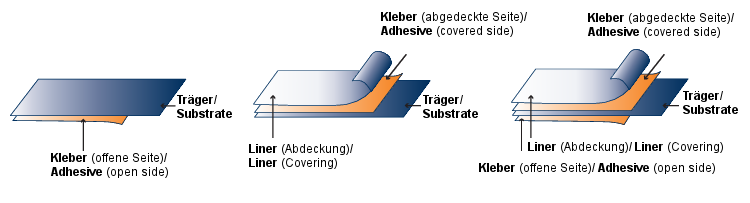

Structure of an adhesive tape