The permeability to water vapor depends in many cases on parameters:

Film thickness

Humidity difference

Temperature

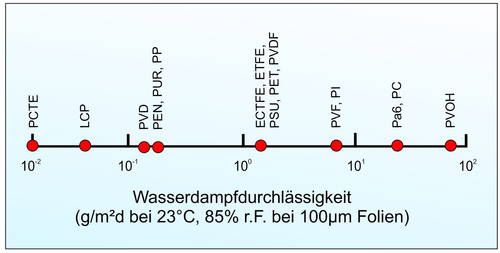

However, some engineering plastics are more suitable as vapor barriers than others. The graph represents a rough guide in terms of water vapor permeability per square meter per day in grams of water.

Water vapor (and of course a variety of gases) penetrates thin layers of polymers (films) relatively well. They allow the passage (permeation) of water molecules through the material. The world-famous Gore membrane for outdoor clothing has a particularly high water vapor permeability (WDD) or Water Vapor Transmission Rate (WVTR). Packaging and barrier films, on the other hand, try to be a particularly good barrier to water vapor diffusion.

In principle, the measurement involves exposing one side of the film to a specified humidity (e.g. 90% rel. H). On the other side, the amount of water that has permeated through the barrier is measured by means of a dried carrier gas (e.g. DIN EN ISO 15106).

The measured value for the amount of water vapor that can penetrate a film is given in grams per square meter per day: gr/(m² x d).

| Material | Film thickness | WDD in gr/(m² x d) *) |

| PVDF | 50 µm | 0,2 |

| PCTFE | 19 µm | 0,42 |

| PPS (Torelina™) | 25 µm | 0,9 |

| ETFE | 100 µm | 1,5 |

| PFA | 50 µm | 2 |

| PVF | 25 µm | 5 |

| PEEK (Aptiv™) | 50 µm | 6 |

| PEN (Teonex®) | 25 µm | 6,7 |

| FEP | 25 µm | 7 |

| PET (Mylar®) | 25 µm | 18 |

| PTFE | 200 µm | 18 |

| PEI | 50 µm | 27 |

| PA 6 | 25 µm | 60 |

| PI (Kapton®) | 25 µm | 80 |

| Kapton® FMT | 30 µm | 17,5 |

The water vapor pressure at room temperature is about 23.4 mbar, but increases exponentially with temperature (100°C: about 1013 mbar). This fact should always be taken into account when comparing data in data sheets of different plastic films. The increased vapor pressure also substantially increases the amount of permeation per area and time.

As already indicated above, Gore membranes (microporous plastic film) have a particularly low diffusion barrier effect: >>550 gr/(m² x d). In comparison, a considerably thinner PET film (25 µm) allows only about 18 gr/(m² x d) of water vapor through.

Important when comparing different water vapor permeabilities: the values depend very much on the pressure, the film thickness, the temperature and the material itself. This is because polymers with the same designation from different manufacturers can differ considerably. Even the different measurement methods result in significant differences for the same material.

In the case of polyolefins such as PP, PE and thermoplastics such as PVC and PA, the molecular weight (best known: LDPE, HDPE and UHMW-PE) is also decisive for the water vapor diffusion rate.

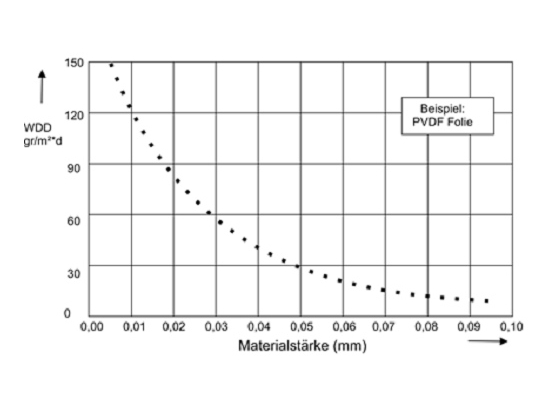

Example: Course of vapor permeability (WVTR, WDD) depending on material thickness

Water vapor permeability of various plastic films